Choosing the Right Partner for PCB Fabrication in Malaysia: Key Considerations

June 17, 2025

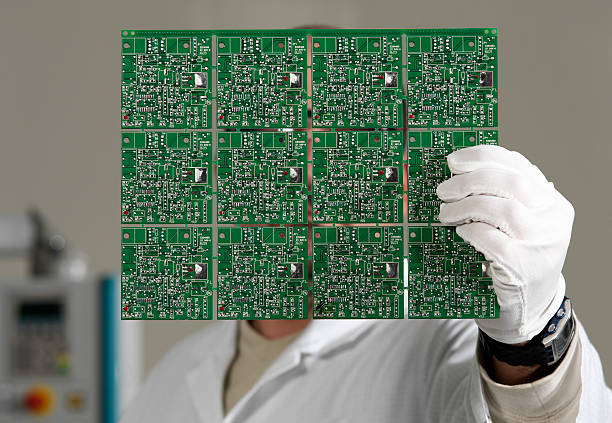

Printed circuit boards (PCBs) form the foundation of modern electronics, enabling functionality across a wide range of applications, from consumer devices to industrial automation systems. As technology evolves, the demand for precision, reliability, and scalability in PCB production grows stronger. For companies seeking quality and speed, partnering with a trusted provider of PCB fabrication in Malaysia is a critical decision.

Understanding PCB fabrication in Malaysia

PCB fabrication refers to the process of manufacturing the actual board structure, etching, layering, and drilling to create the pathways for electronic signals. This differs from PCB assembly, which involves placing and soldering electronic components onto the fabricated board. In Malaysia, industries such as automotive, telecommunications, medical equipment, IoT, and consumer electronics depend heavily on efficient and high-quality PCB solutions.

With Malaysia’s position in the global electronics manufacturing chain, the country continues to attract companies looking for reliable PCB fabrication. The availability of technical expertise and cost-effective operations makes it a preferred choice for both local and international businesses.

Why Malaysia is a preferred hub for PCB fabrication

Several factors contribute to Malaysia’s growing presence in the PCB manufacturing industry. Geographically, Malaysia offers a strategic location in Southeast Asia, providing convenient access to regional and global markets. The country also boasts a skilled engineering workforce that supports both design and manufacturing phases.

Infrastructure plays a key role as well. With robust industrial parks and connectivity, Malaysian facilities can handle large-scale production without sacrificing quality. Competitive pricing, when compared to other manufacturing hubs, gives businesses a cost advantage while maintaining high standards.

Furthermore, Malaysia’s government continues to invest in the electronics and electrical (E&E) sector, offering incentives that encourage growth and innovation in PCB technologies.

What to look for in a PCB fabrication partner

Choosing the right partner for PCB fabrication in Malaysia involves more than just cost considerations. Businesses should prioritise partners who meet international quality standards, such as ISO certifications, to ensure product consistency and compliance.

Capabilities are equally important. Look for providers who offer multilayer PCB fabrication, flexible board options, and customisation services. The ability to handle prototyping as well as mass production demonstrates technical agility and responsiveness.

Lead time also matters. In fast-moving industries, delays in PCB fabrication can impact the entire product lifecycle. A reliable local partner should deliver on time while offering clear communication and support throughout the project.

Compatibility with global supply chains is another factor to consider. A partner that understands both local regulations and international requirements can help streamline logistics and reduce downtime.

How Foz One supports PCB fabrication in Malaysia

Foz One delivers end-to-end PCB fabrication solutions tailored for Malaysia’s diverse industries. With a focus on precision and speed, the company produces single-layer, double-layer, and multilayer PCBs suited for a range of applications. Whether the need is for rigid or flexible boards, Foz One combines advanced technology with strict quality control to ensure every board meets exacting standards.

Clients benefit from a streamlined process that includes consultation, prototyping, fabrication, and support. Foz One’s team brings years of hands-on experience, ensuring that each project aligns with technical requirements and business goals. The company’s commitment to fast turnaround times and scalable production makes it a dependable choice for growing manufacturers.

Conclusion

In a rapidly evolving electronics landscape, securing a reliable provider for PCB fabrication in Malaysia ensures continuity, quality, and competitive advantage. By partnering with a company like Foz One, businesses gain access to cutting-edge capabilities, expert support, and consistent delivery—key ingredients for success in the global electronics market.